Laser cuts and combines

Lasers as universal tools

Lasers are universal tools that can be used not only to cut and remove materials, but also to join them. The laser beam heats the material in the focus area above its melting temperature. The resulting melts mix and solidify again to form a solid bond. This process takes only a few milliseconds and requires no additional materials. However, laser welding without additional material requires very small gap widths. For large gap widths or to repair defects, we can alternatively feed welding wire.

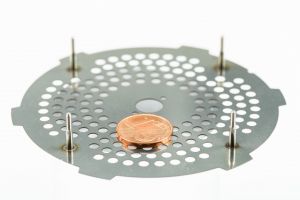

Precision through micro welding

Micro welding, also known as precision welding, offers you many advantages. By focusing the laser beam on a small welding point (Ø 0.2 mm to 2.0 mm), the weld seams are very precise and narrow. The associated controlled heat input reduces the heat-affected zone and minimizes thermal distortion.

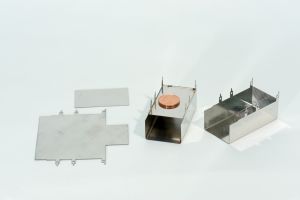

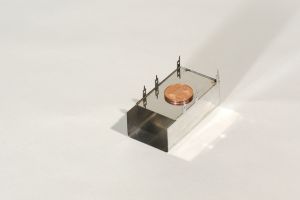

Flexible applications

Laser beam welding is an alternative to gluing, soldering, or other welding processes. It enables the joining of different metals with different melting points. Thanks to the precise energy input, we can weld thin, filigree workpieces and the finest structures. It is also possible to join different material thicknesses without any problems.