Services for the printed circuit board industry

Established service provider in PCB processing

LiMaB GmbH has established itself as a service provider for PCB processing in Germany and neighboring European countries. The use of lasers in the manufacture of PCBs has set new standards in terms of quality and precision. With innovative laser technology, we offer contour cutting of printed circuit boards, the production of microvia holes in HDI printed circuit boards, and laser structuring of printed circuit board surfaces. Our ultra-short pulse (USP) laser system cuts, drills, and structures a wide range of printed circuit board materials and technical plastic films with high precision. The thermal impact on the material is extremely low.

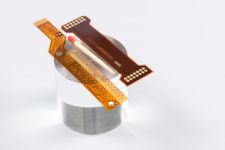

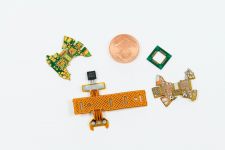

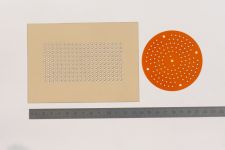

Contour cutting up to 600 x 600 mm

LiMaB has been laser cutting the outer contours of flexible or rigid-flex printed circuit boards with panel sizes up to 600x600 mm since 2002. Each customer uses individual technologies and material combinations in the manufacture of their printed circuit boards. The resulting diversity constantly presents new challenges in laser processing. This places particularly high demands on us to select the optimum laser parameters for each job. For our experienced employees, the supposed difficulties are a daily incentive to execute incoming orders with high quality and on time.

Plastic films for medical technology and equipment manufacturing

In addition to cutting PCB contours, there is a growing demand for cutting plastic films for use in medical technology and equipment manufacturing. The thinnest films are just 7 µm thick. We implement further applications based on specific requests and samples.

Microvia and through holes

Laser drilling of microvias in printed circuit boards is a special discipline that distinguishes LiMaB GmbH as a recognized service provider to the printed circuit board industry. Microvias and blind holes (blind vias) with diameters from 30 µm to 300 µm are drilled in various PC material. Through holes with diameters of 50 µm or more can be created in multilayer printed circuit boards up to 0.5 mm thick.

Precise laser structuring of solder resist

To prevent solder bridges, printed circuit boards are coated with solder resist before machine soldering. Misprints in solder resist masks occur only sporadically. However, this usually affects larger delivery batches. Since experience has shown that replacement is time-consuming and costly, we offer our customers reworking services. The solder resist is precisely structured away with a laser. The laser beam, which is only 20 µm wide, scans the affected areas and exposes the soldering surface again.

Cover layers

Cover layers protect the conductor tracks from corrosion and are an alternative to solder resist. The cover layers are laminated onto the flexible or rigid printed circuit boards. Depending on the fineness of the copper pad openings, they can be applied to the cover layer before or after. Both variants are possible with our laser systems.

Fast and reliable production

We process your small series within 1–3 working days. Express production of individual items within a few hours is possible by arrangement. When laser processing printed circuit boards and plastic films, special care must be taken when handling the sensitive and valuable materials. Even the smallest errors can render the entire circuit board unusable. Consistent intermediate and final inspections based on the dual control principle, supported by measuring and testing systems, guarantee our high quality. Upon request, measurement and test reports can be created and supplied.

Our range of services

- LiMaB GmbH's range of services in the field of circuit board and plastic processing includes:

- Distortion-free and low-smoke laser contour cutting of flexible and rigid-flexible circuit boards and cover layers

- Laser drilling of microvias, blind holes, and through holes in circuit boards

- Laser structuring of solder resist and opening of cover layers

- Laser cutting of thin plastic films, plastic fabrics, and plastic screens for medical technology and equipment manufacturing

- Laser fine processing of laminated, metallized, vapor-deposited, or other coated plastic films

- Laser fine cutting of paper and thin insulation materials