The beginnings with laser marking

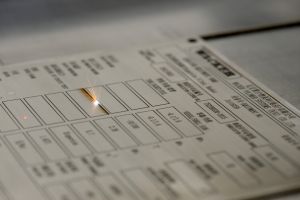

It all started with laser marking. Since 1991, laser marking, laser engraving, and laser etching have been part of LiMaB's range of services.

A wide range of processing options

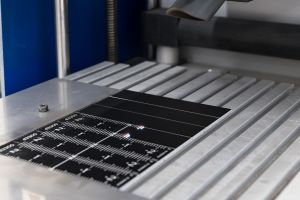

By selecting the pulse repetition frequency, laser power, and marking speed, different effects can be achieved on a wide variety of materials. The fiber laser used has proven particularly effective for processing metals and some plastics. The marking options are very diverse.

Materials and processes

- With coated or multi-layer materials, such as color-anodized aluminum or laser foils, targeted color removal is performed.

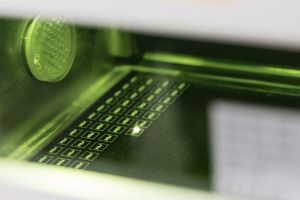

- Plastics with color pigments are thermally altered by the laser and thus locally discolored—the best-known example being computer keyboards.

- When laser engraving metals or plastics, only a few micrometers of material are removed. However, the engraving is permanent and tamper-proof.

- The most decorative form of laser marking is the tempering discoloration of some metals. In this process, the surface oxidizes due to laser heating and produces a high-contrast, dark color.

Advantages of laser marking

Laser marking can be used to mark different workpiece shapes and materials at high speed. The contour sharpness is impressive. Laser marking is abrasion-resistant and resistant to chemicals and solvents. The success of this marking technology lies in its combination of precision and forgery resistance.

Flexible layouts and design options

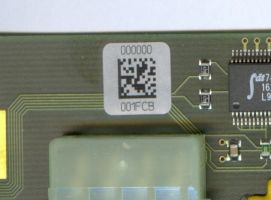

We offer you a wide range of flexible marking layouts. Single-line and TrueType fonts, circular and circumferential marking, barcodes and 2D codes, vector and pixel graphics, and CAD drawings are all possible. We would be happy to provide you with sample markings.

Our laser marking services

We mark, label, and engrave for you:

- Fake-proof laser labels in any shape made from two-layer laser foils in black/white, white/black, silver/black, and special colors (red, blue, yellow)

- Temperature- and chemical-resistant stickers for components, circuit boards, and assemblies with sequential numbering or 2D codes

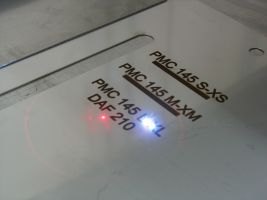

- Type plates, rating plates, boiler plates, scales, and badges made of stainless steel or anodized aluminum – individually designed with company logos, special characters, graphics, or foreign-language text

- Supplied front panels, housings, and switch boxes made of stainless steel

- Serial numbers, product data, and type designations on machine components, standard parts, instruments, tools, and components