Thin with “sharp” edges

Precision in metal and plastic films

As a manufacturer of precision parts made from ultra-thin sheet metal (from 5 µm thick) and thin sheet metal (up to 3 mm thick) as well as plastic films (from 7.5 µm thick), we have successfully conquered market niches. Since 1993, LiMaB GmbH has been known as a reliable service provider in Germany and neighboring European countries. We manufacture high-precision laser cuts for our business partners in the electronics and circuit board industry, mechanical and equipment engineering, and medical technology. Depending on the type and thickness of the material, we achieve accuracies of a few micrometers.

Wide range of materials

We process sheet metal foils made of stainless steel, spring steel, tinplate, aluminum, brass, titanium, copper, bronze, and other thin metals. In addition to laser fine cutting of metal foils, we offer laser fine processing of laminated, metallized, vapor-deposited, or other coated plastic foils.

Flexible manufacturing with modern laser technology

We produce precisely machined molded parts in small and medium series, but also cost-effectively as individual pieces. We manufacture flexibly and quickly according to your CAD files or customer drawings.

LiMaB GmbH's machinery includes laser systems with outputs ranging from a few watts to 3 kW. Our laser systems are: Nd:YAG lasers, fiber lasers, and ultrashort pulse lasers. We use the different laser powers and wavelengths optimally for your application. We cut simple geometric outlines or complicated contours without special tools. There are virtually no limits to the variety of shapes.

Supplementary mechanical processing

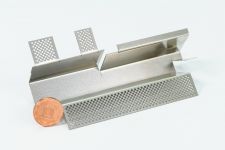

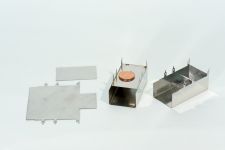

In addition to laser cutting, LiMaB GmbH offers mechanical post-processing of precision parts. Of course, we deliver your laser-cut parts with fitting holes, countersinks, and internal threads. We manufacture the smallest bent parts and various edge parts on our modern CNC bending machines for folding and swivel bending. We achieve a high accuracy of 20 µm and 0.2° without additional tooling costs.

Finishing and surface treatment

After production, the cutting edges of the precisely cut laser parts are carefully post-treated and the surfaces are finished as required. Using disc centrifugal machines, we can mechanically deburr the workpieces, round off the cutting edges, and achieve a high surface quality.

Quality assurance at the highest level

For quality assurance purposes, the tiny precision parts are examined under a microscope. In the case of small parts with tight tolerances, the inspection is carried out using a digital measuring projector with a high measuring accuracy of 2 µm.

LiMaB GmbH's range of services in the field of laser fine cutting includes:

- Precision molded parts and fine-cut parts such as retaining springs, connectors, contact elements, clips, brackets, clamps, and countless small parts for a wide range of applications

- Spacer plates, intermediate layers, compensation foils, lining plates, and shim plates for mechanical engineering in small and large dimensions, from 10 µm thickness and up to 2500 mm length, as well as with any geometric contours

- Sheet metal blanks up to 3 mm thickness

- Printing stencils, vaporization masks, covering stencils, shadow masks for selective and adjusted coating, printing, or shading of substrates or surfaces

- Electronics housings made of tinplate, shielding hoods for electronic components, sensor housings, shielding housings for small circuit boards, micro housings for mini assemblies

- Washers, spacer rings, spacer discs, tuning discs, and fitting rings in special sizes

- Spacer rings, seals, washers, fitting discs, sealing rings, and spacer discs in universal sizes

- Laser precision machining of laminated, metallized, vapor-deposited, or other coated plastic films

- Laser cutting of plastic and metal fabrics for filters, screens, and shields

- Laser fine cutting of paper and thin insulation materials