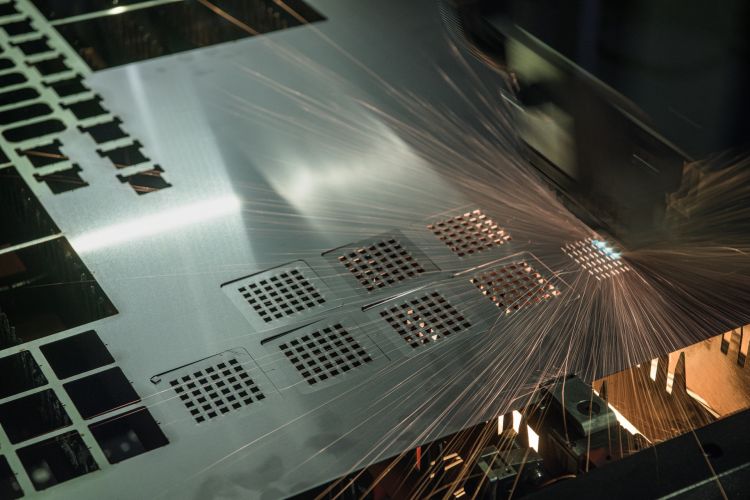

Laser cutting

As a manufacturer of precision parts made from ultra-thin sheet metal (from 10 µm thick) and thin sheet metal (up to 3 mm thick) as well as plastic films (from 7.5 µm thick), we have...

Printed circuit boards & Films

Printed circuit board manufacturers in Europe are increasingly becoming specialists in sophisticated technologies (multilayer, flex, and rigid-flex) ...

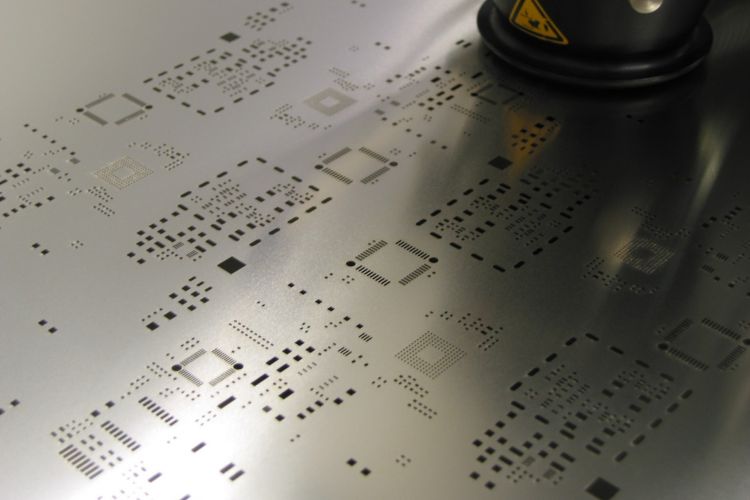

SMD - Stencils

The application of solder paste or adhesive to unassembled printed circuit boards in SMT (surface mounting technology) is currently mostly carried out in ...

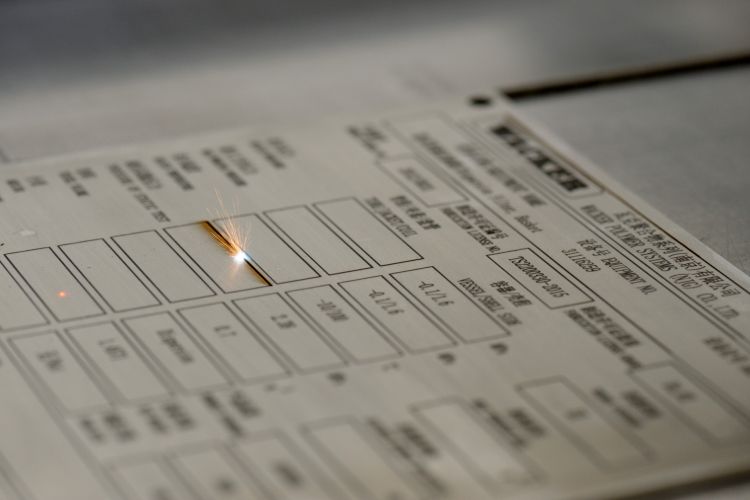

Laser marking

It all started with laser marking. Since 1991, laser marking, laser engraving, and laser etching have been part of LiMaB's range of services...

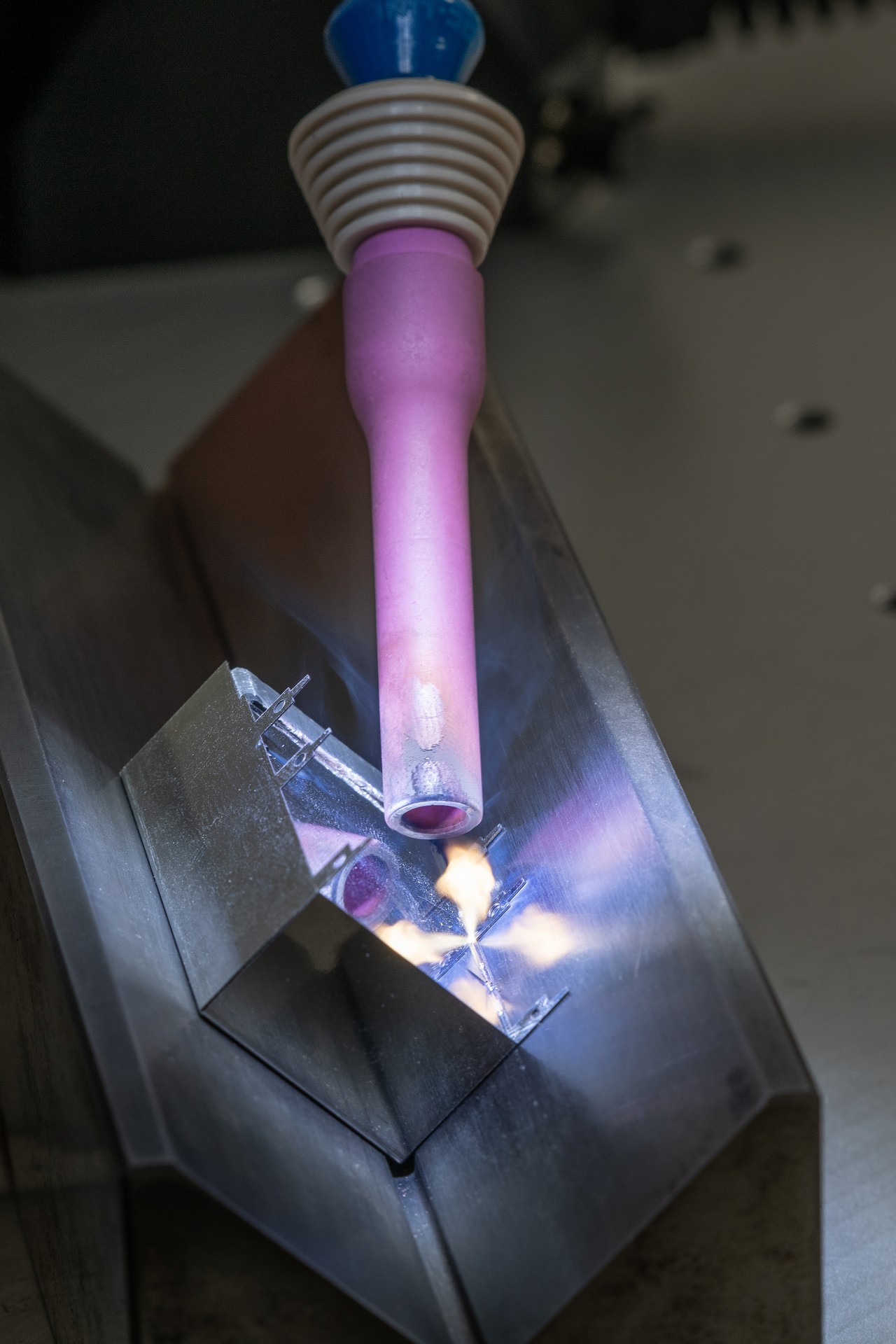

Laser welding

With the universal tool that is the laser, we can not only cut and remove materials, but also join them together. The laser beam heats the material in the focus area above its melting temperature. The resulting melts mix together and solidify again to form a strong bond. This process takes only a few milliseconds and requires no additional materials. However, laser welding without additional material requires very narrow gap widths...